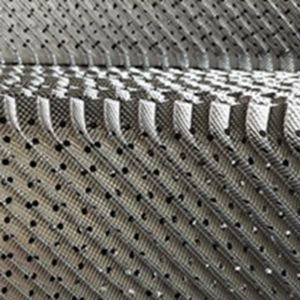

The underlying principle behind DODGEN DSXL devolatilization involves the rapid and even heating of the polymer to a certain temperature, and/or the addition of additives that help the volatiles escape, and then the polymer disperse evenly in the separation tank, the volatiles are released from the polymer matrix as a result.