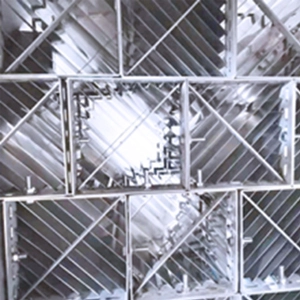

Falling Film Evaporation is a process in which the liquid feed is introduced into the upper header box of the heating chamber of a falling film evaporator, and then evenly distributed to each heat transfer tube by a liquid distribution and film-forming device. Under the effects of gravity, vacuum induction, and gas flow, the liquid forms an even film that flows down from top to bottom. In the distillation unit, the vapor phase directly enters the tower for distillation, while the liquid phase is discharged from the separation chamber or circulated back into the evaporator by the pump.