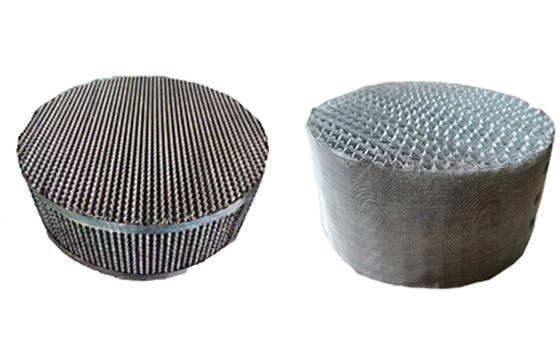

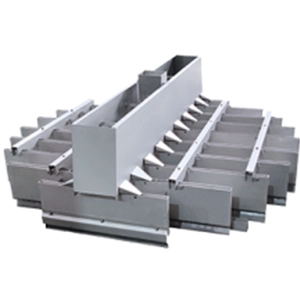

Combined with worldwide advanced technology and engineering experience, the tower internals designed by structured packing manufacturer DODGEN are optimized according to fluid dynamics model and manufactured in strict accordance with our quality management measures to ensure the quality.