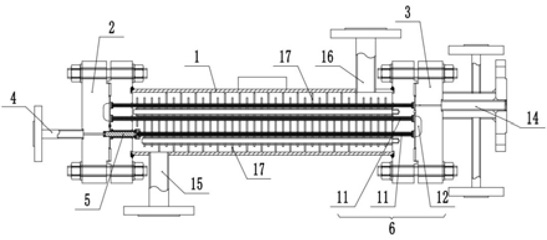

The invention belongs to the field of reaction equipment technology, specifically presents a microchannel fast reactor, including a housing, the housing is provided with several microchannel reaction units, each microchannel reaction unit includes a microdistributor and a reaction tube, the microdistributor is provided with cavity, the cavity is provided with a separator, the separator separates the cavity into a number of independent fabric cavities, the separator includes several horizontal parts and vertical parts, the microdistributor is provided with a feed inlet connected to the corresponding fabric cavity, the reaction tube is connected to the cavity away from the feed inlet. In the invention, the cavity of the microdistributor is separated into special fabric cavities by the separators, so that the reaction material flows through the fabric cavities to form multiple layers of material set up alternately, which effectively increases the contact area of the reaction material and improves the mass transfer efficiency of the reaction material, thus shortening the reaction time and improving the production efficiency.

Microchannel reactor, microreactor for short, has the advantages of small size, large surface area and better mass and heat transfer than tank reactor. Conventional microreactor typically has Y-shaped channels, where the channel introducing the first fluid and the channel introducing the second fluid intersect in a Y-shape to form a single converging channel, and the fluids supplied to each channel converge with each other at the intersecting part of the channel and then diverted to the next Y-shape channel to achieve diffusion and mixing of the fluids. However, although the Y-channel is able to diffuse and mix the fluids, when the fluids meet at the intersection of the channels, the contact area between the first fluid and the second fluid is limited (the flow area of the Y-channel is small, so is the contact area of the fluids), so several Y-channels need to be set up to ensure a complete fluid reaction, which results in a relatively long fluid reaction time and relatively low production efficiency, which is not conducive to rapid production. Therefore, there is an urgent need to design a microreactor that can improve production efficiency.