In today's era of limited resources and growing environmental awareness, organic synthesis chemistry faces unprecedented challenges. While enhancing product quality and production efficiency, it is crucial to reduce energy consumption, labor costs, risks, and environmental impact. To achieve these goals, continuous flow chemical technology has emerged as a revolutionary modern technology in the field of chemical engineering. For reaction systems with high exothermicity, uncontrolled temperature, and uneven concentration, continuous flow chemistry significantly reduces manual intervention and operating costs, enabling sustainable resource utilization and environmentally friendly production, while substantially lowering production safety risks. In recent years, continuous flow production has gained high attention from governments, societies, and businesses. Many companies are increasing investments in new equipment and technologies to embrace this trend.

Continuous Flow Reaction Technology

Continuous flow reaction technology is an efficient method of chemical synthesis that enables the continuous synthesis of multi-step reactions. It achieves efficient, rapid, and controlled chemical synthesis by allowing reactants to undergo reactions under continuous flow conditions. In traditional batch reactions, multi-step reactions require multiple reactions, each needing separation and purification of the products, resulting in significant time and resource wastage. In continuous flow synthesis, multi-step reactions can be completed in the same reactor, facilitating efficient continuous synthesis.

The application of continuous flow reaction technology spans various fields, including high-throughput synthesis, heterogeneous reactions, catalytic reactions, highly exothermic reactions, and low-temperature reactions. It provides industries with efficient, safe, and sustainable solutions, injecting new momentum into the high-quality development of pharmaceuticals, fine chemicals, new materials, and other fields.

Notably, the pharmaceutical and fine chemical industries are among the typical application areas of continuous flow technology. In the pharmaceutical field, continuous flow reaction technology aids in the synthesis of pharmaceutical intermediates and drugs, offering high purity and yield while reducing waste and pollutant generation for greener and more sustainable drug manufacturing. In the fine chemical industry, continuous flow technology is also used for producing high-value chemicals, enhancing industry competitiveness. Additionally, the application of continuous flow technology benefits the field of new materials, enabling the preparation of novel materials such as nanomaterials and functional materials with broad prospects in electronics, energy, and environmental protection.

Advantages of Continuous Flow Reaction:

· Improved comprehensive utilization of raw materials

· High conversion and product yield rates

· Low by-product yield, addressing high investment and environmental pressure from by-products

· Miniaturization of equipment

· Process integration

Compared to traditional batch reactions, continuous flow multi-step synthesis establishes a complete synthetic system. Apart from technical complexity, ensuring good control in successive reactions within the connected multi-step reactions is key to the success of continuous flow multi-step synthesis, relying on innovative chemical methods and the design and optimization of online separation technologies.

DODGEN Efficient Continuous Flow Reaction Technology

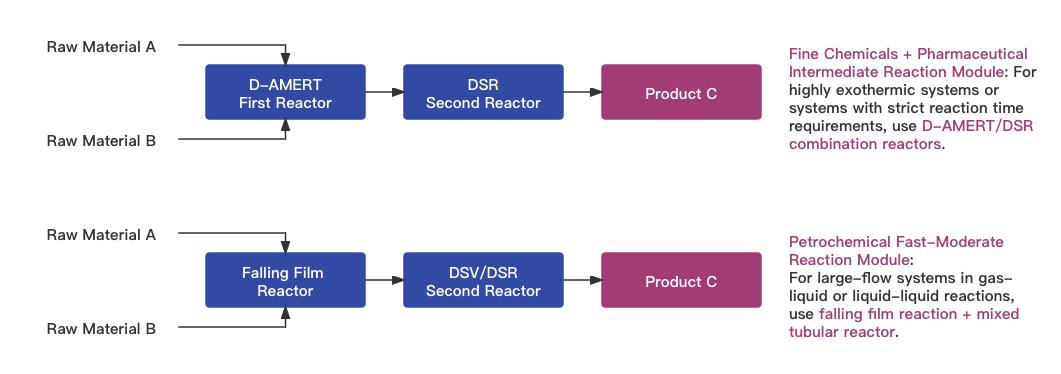

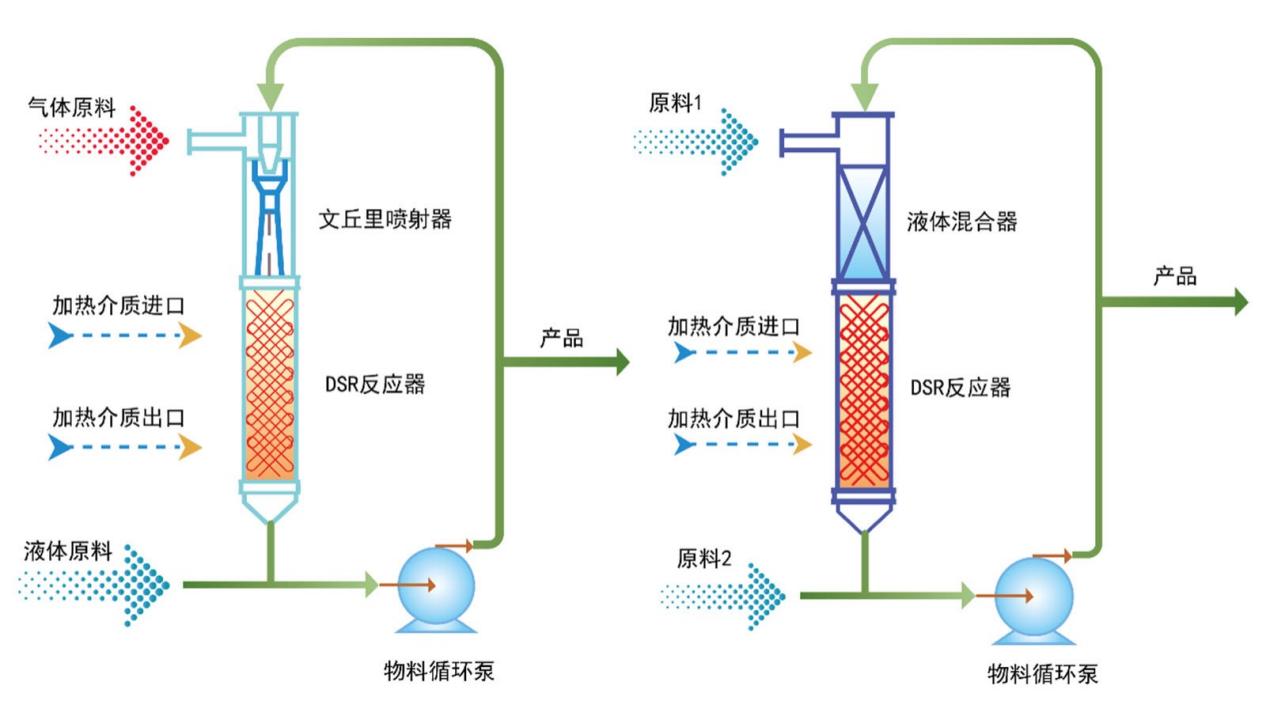

DODGEN Company possesses rich experience and advanced technology in the field of continuous flow reaction technology. Two sets of independent parallel continuous flow reaction systems have been developed to meet the requirements under different reaction conditions. One system is suitable for fine chemicals and pharmaceutical intermediate reactions, especially for highly exothermic systems or liquid-liquid reactions. The other system is applicable to the rapid and moderate reactions in the petrochemical industry, including large-flow systems for gas-liquid reactions. These two systems incorporate advanced technologies such as D-AMERT high flux micro reaction technology, DSR flat push-flow mixing reaction technology, FFR falling film reaction technology, DSV rapid reaction technology, and circulating reaction technology, providing customers with multiple options to meet different reaction needs.

Applications of DODGEN Continuous Flow Fast-Moderate Reaction Technology:

· Sodium cyanide reactor

· Acrylonitrile reactor

· Hydroxynitrile reactor

· Aniline-based nitrile reactor

· Glycine reactor

· Carbon dioxide absorption reactor

· Ammonia absorption reactor

· Sodium mercaptide reactor

· Polylactic acid reactor

· Sulfonation reactor

Applications of DODGEN D-AMERT Micro Reactor:

The micro reactor can be applied to nitration of aromatics, direct oxidation of cyclohexene to adipic acid using hydrogen peroxide, photocatalytic oxidation of thiol to disulfide, photocatalytic trifluoromethylation of aromatics and heterocycles, palladium-catalyzed oxidation of o-xylene to 3,3',4,4'-tetramethylbiphenyl, copolymerization, continuous sulfonation reactions, etc.

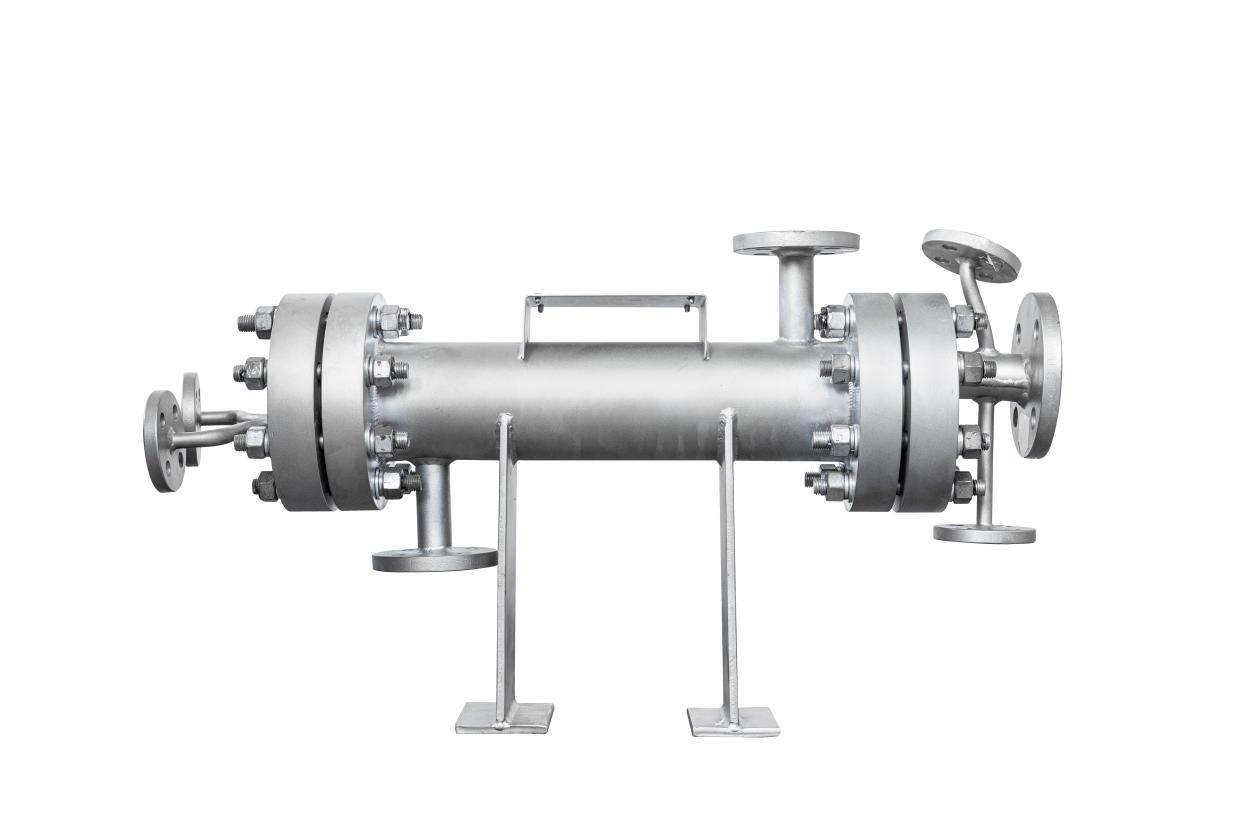

DODGEN Flat Push-Flow/Piston Flow/Tubular Reactors:

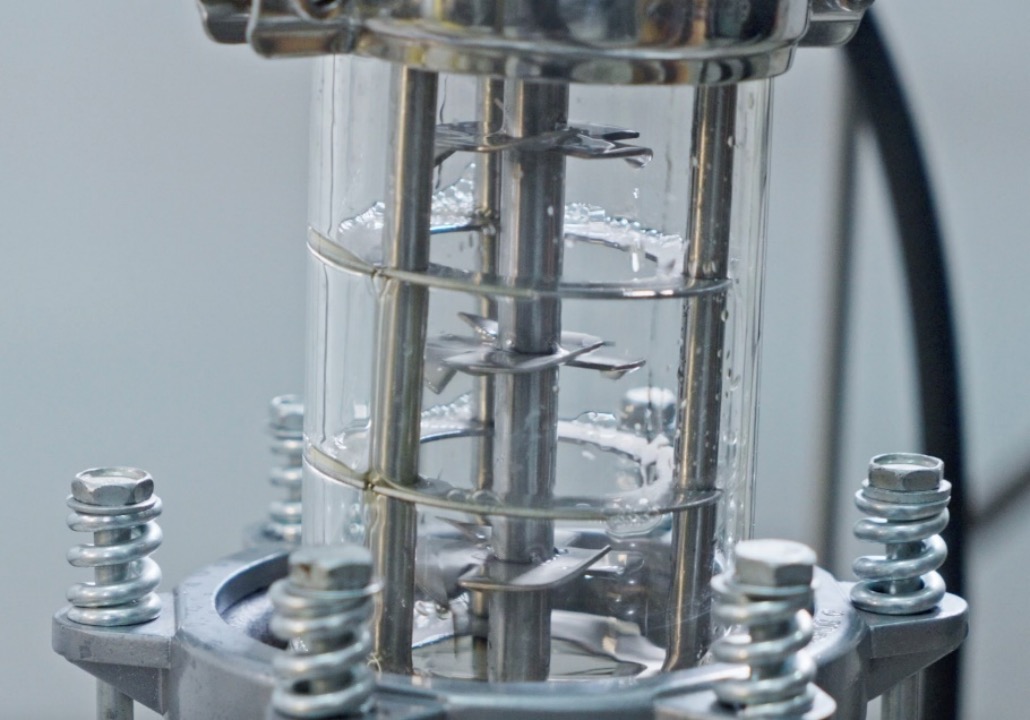

Based on the principle of static mixing, different forms of mixing elements are used to shear, disperse, and mix reactants forcefully in the pipeline according to the physical properties and reaction conditions of different reactant systems, providing a large reaction area and heat exchange area. This ensures optimal concentration and temperature uniformity of reactants, with a narrow distribution of residence time.

Typical applications: sulfonation, nitration, peroxidation, alkylation, polyester polymerization.

Applications of DODGEN Circulating Reactor:

Nitration reaction, hydrogenation reaction, oxidation reaction, cyclization reaction, carbonylation reaction, ethoxylation reaction, alkylation reaction, amination reaction, chlorination reaction, etc.

Post-processing Steps in Continuous Flow Processes

Post-processing steps in continuous flow processes are often overlooked by process developers. In actual processes, post-processing involves numerous equipment, substantial investments, high yield losses, large amounts of pollutant emissions, significant safety risks, and high work intensity.

DODGEN Continuous Extraction Technology

DODGEN efficient rotor extraction tower, through careful hydraulic design, precise fluid dynamics modeling, and extensive testing and practical application verification.

Typical applications: phenol-containing wastewater, acetic acid recovery, solvent recovery, lactic acid purification, lithium extraction from salt lakes, lubricating oil refining, food-grade phosphoric acid, vanadium extraction from titanium dioxide wastewater, inorganic substance extraction, catalyst recovery, high-value organic compound recovery, and extraction.

DODGEN Continuous Falling Film Crystallization Technology

DODGEN continuous falling film crystallizer allows precise temperature control and fully automatic continuous control for large-scale efficient purification.

Typical applications: isomers separation, electronic chemicals, thermosensitive substances, azeotropic systems, monomers in polymerization, etc.

DODGEN continuously optimizes its continuous flow technology towards energy efficiency, environmental protection, and intensification. Continuous flow integrated equipment features efficiency, continuity, and automation. The feasibility of continuous flow in complex organic experiments is gradually being validated, and the future of organic chemical engineering will continue to move towards intelligence.