In recent years, the semiconductor application and consumer market demand have experienced stable growth. Entering the semiconductor materials (electronic chemicals) field through endogenous R&D or external mergers and acquisitions has become a common pattern for chemical companies seeking transformation in recent years. Successfully transformed companies not only achieve faster industry growth but also receive higher market valuations, ushering in a wave of dual growth. In the rapid development of the domestic semiconductor industry, related electronic chemicals companies also seize the opportunity for domestic substitution.

On the policy front, various countries worldwide have indicated their intention to restrict the export of chemicals used in semiconductor manufacturing to China to prevent it from losing technological advantages. In response, China has continuously introduced supportive measures to stimulate the development of the electronic chemical industry. For example, in the first quarter of 2021, the China Petroleum and Chemical Industry Federation released the "Guidelines for the Development of the Petroleum and Chemical Industry in the 14th Five-Year Plan." Additionally, in 2023, the Beijing Economic and Information Bureau and the Beijing Finance Bureau issued the "Implementation Guidelines for the Development Fund of High-end Industries in Beijing in 2023 (First Batch)." Various segments of the semiconductor industry chain urgently need comprehensive development to cope with industrial development under export restrictions and enhance China's competitiveness in high-tech.

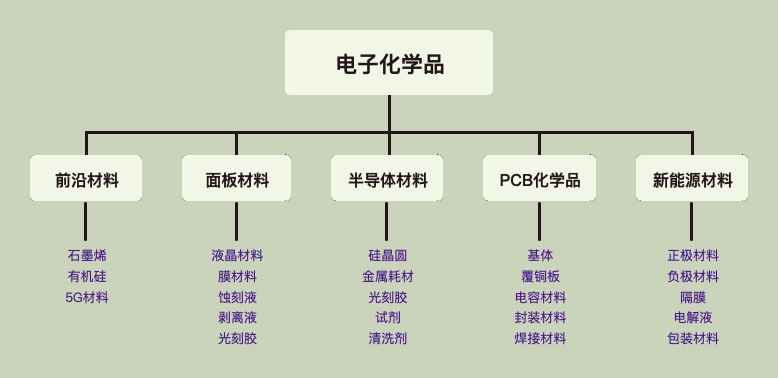

Electronic chemicals are used in various fields such as integrated circuits, flat panel displays, new energy batteries, and printed circuit boards. As a strategic emerging industry, electronic chemicals in China are currently in a rapid growth phase in their life cycle, with enormous future development potential.

Wet electronic chemicals are essential components, particularly in wet processes for microelectronics and optoelectronics (mainly including wet etching, cleaning, lithography, interconnection, etc.), also known as "ultra-pure high-purity reagents" or "electronic-grade reagents." They are divided into general wet electronic chemicals and functional wet electronic chemicals.

Furthermore, the development of new energy vehicles is driving research into new battery technologies and related electrolytes. There is a peak in demand for high-purity carbonate materials. The electrolyte in lithium-ion batteries is equivalent to the "blood" of the battery, playing a crucial role in battery performance. Carbonate series additives are the largest category in current lithium-ion battery electrolytes, serving as organic film-forming additives and overcharge protection additives, crucial for improving battery capacity, cycle life, and overall performance.

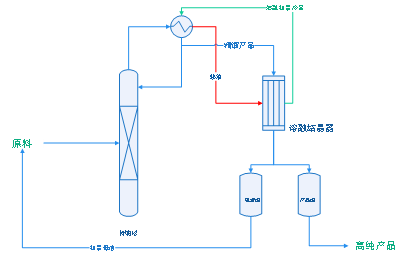

The application of DODGEN's distillation-coupled melt crystallizer technology in high-purity electronic chemicals

With the continuous upgrading of electronic components and lithium-ion battery technologies, the purity requirements for wet electronic chemicals such as phosphoric acid used for cleaning and etching, as well as electrolytes for lithium-ion batteries, are increasing. As a specialist in reactions and separations, DODGEN can provide various separation solutions to break through the technological barriers of high-purity electronic chemicals.

In products such as electronic-grade phosphoric acid, hydrogen peroxide, and lithium-ion battery electrolyte additives, the distillation-coupled melt crystallization technology can help achieve purity levels of 99.9999% or higher. This meets the stringent requirements for semiconductor high-purity solvents and lithium-ion battery chemicals, providing assurance for the finished product yield of electronic components, the charging performance of lithium-ion batteries, and their reliability.

Pure chemical products using only distillation technology have drawbacks such as high reflux ratios and energy consumption, ultimately leading to high costs. In the distillation process, the removal of trace impurities becomes more challenging with each increase in purity level, requiring a doubling or even multiple times increase in distillation reflux ratio, leading to a sharp increase in energy consumption. Melt crystallization exploits the characteristics of obtaining pure substances and low eutectic mixtures during the crystallization process. When the purity of the raw material for melt crystallization is low, due to the low eutectic point close to the mixture, the disadvantage of low yield or even inability to crystallize pure substances may occur. However, the purification of lower purity materials is precisely the advantage of distillation. Additionally, since the operation temperature of melt crystallization is near its melting point, the operating temperature must be lower than the condensation temperature at the top of the distillation column, making it possible to use the heat from the top of the distillation column for melt crystallization. Therefore, coupling distillation and crystallization technologies, leveraging their respective advantages, achieves optimal yields and purity.

Today, the preparation and purification technology of key electronic chemicals have become a pressing "bottleneck" issue. DODGEN's various separation and purification solutions can inject new ideas into the semiconductor and new energy industries, jointly breaking through the technological barriers to industry development.