This lecture is jointly organized by Shanghai DODGEN Chemical Technology Co., LTD., Shanghai New Material Association and China Chemical Enterprise Management Association,it attracted more than 200 industry experts, research and development members,and many chemical practitioners and entrepreneurs to participate in.Kang xiaoling,the general manager of Shanghai DODGEN Chemical Technology Co., LTD.,gave a detailed introduction to the green and low carbon ultra-pure technology of "melt crystallization", and discussed the practical problems in the production and application of this technology. Here is the selection of the lecture.

Technical Background

By the end of 2019, China has been the world's largest country in chemical production and consumption,In recent years, it has maintained rapid growth with an average annual growth rate of about 6%.

With the rapid development of the chemical industry, carbon dioxide emissions are also rising rapidly.The zero-carbon transformation of China's chemical industry is crucial to the national goal of carbon neutrality, and it is also significant to the low-carbon transformation of the global chemical value chain.

In the energy consumption structure of the chemical process, separation accounts for 80%.Especially in the field of electronic chemicals and new materials, the separation of high-purity chemicals is faced with the bottleneck of high energy consumption and technical difficulty.Is there a solution to the problem that is so prevalent today that it can be widely applied and promoted?In the context of carbon neutrality in the chemical industry, the green and low carbon separation technology - melt crystallization, is a good technical choice.Melt crystallization or melting crystallization coupling technology solutions can achieve the separation of high-purity substances, energy saving and emission reduction, improve product revenue and the flexible adjustment of product grade and other values, which will be more widely concerned in the future.

Technology Survey

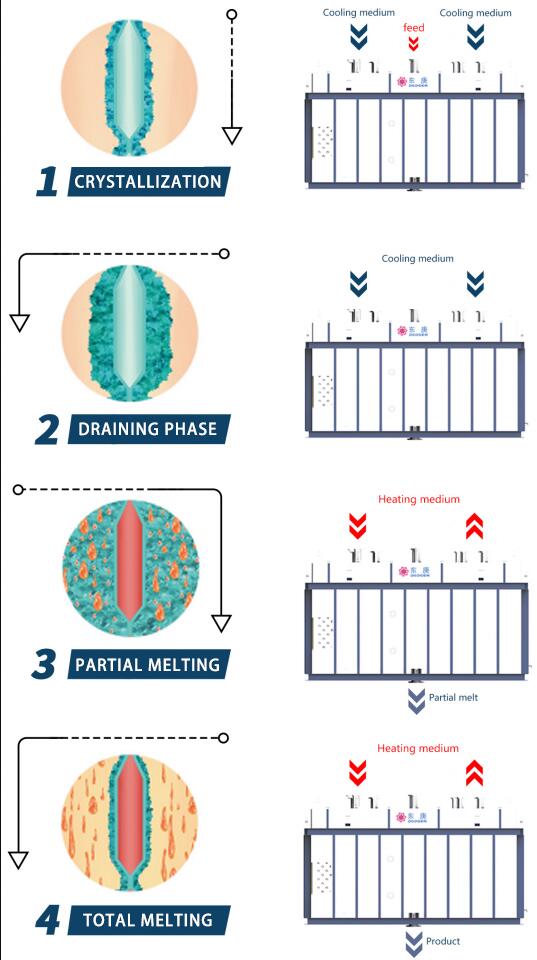

Falling film crystallizers and static crystallizers are very important equipment in the melt crystallization process.The left side of the figure below is the double falling film mould provided by DODGEN, and the right side is the static mould.

The falling-film mould adopts the dual-system design of heat medium and material with parallel amplification to achieve high efficiency and steady control of mass and heat transfer and achieve the goal of low carbon operation.The advantages of falling film crystallizer are:

As a supplement to the falling film mold, the production efficiency of the static mold is relatively low.However, in the case of complex material system, and the device with small mother liquor product recovery and processing capacity, static mold and falling film mold can complement each other.

For the whole melt crystallization process system, chemical processing company DODGEN has established a complete set of technical innovation system,which covers the whole process from process design, key equipment, sustainable innovation research and development, technology application and customer service.Especially in the technology application system, we have established a wide range of product application databases, and accumulated rich application experience, to help customers quickly optimize the process flow.In the customer service system, we have established the integration service of small tests, pilot tests and industrial processes, which can help customers to quickly verify the feasibility of crystallization.Meanwhile,with the application of database and modular pilot device, customers could experience the driving service visually in advance.

Application Cases

The product of this project has the characteristics of high boiling heat sensitivity, which belongs to the classic low eutectic phase equilibrium system.The feed concentration of the product is medium-high, the concentration difference and temperature difference between the product and the eutectic point are large, and the driving force of crystallization is high.

The material is directly crystallized from the reaction section,compared with the raw material and product indicators, the crystal purity was increased from 87% of the initial feed to over 99% of the target purity.Because the material contains complex components and polymers, through three to four levels of crystallization, the yield is about 95%, while the direct distillation yield is only 60%.

Comparing the crystallization process, it is found that the energy consumption of crystallization is about 60% less than that of rectification.Considering the comprehensive energy consumption, waste, product yield and other factors, we recommend the use of melt crystallization technology for separation.

Industry Applications and Empowerment

Melt crystallization, the key low-carbon green technology, has a wide range of application prospects in the industry, covering electronic chemicals, petrochemicals, biological chemicals, fine chemicals and new materials.

In such a wide range of industry applications, when your enterprise product separation encountered the following difficulties and problems:

Further purification costs higher energy consumption

Hoping that the purity of the product is over 99.9%, in order to obtain high-purity products

Very low alpha organics

Isomeride

Forms an azeotrope

High boiling point, thermal instability degradation, the melt point between -20°C~220°C

Separation polymerization at high temperature

Composition of complex thermosensitive biosynthetic chemicals

When encountering the above complex problems, melt crystallization will empower you to achieve energy saving and emission reduction of about 70%, green environmental protection, obtain high-purity products, and product yield increased by 20% or higher.DODGEN company's tens of sets of ten thousand tons of system equipment experience escort for customers.