Part01 Sodium Ion Battery Industry Prospects

At present, the energy storage market has multiple technology routes, but the share of electrochemical energy storage has increased rapidly in recent years. Lithium is still the mainstream line in the industry, but with CATL, Sodium sodium and other enterprises into the market, sodium ion batteries are also rising rapidly, becoming the focus of the energy storage market.

In recent years, the research on sodium battery has gradually become mature. As the sodium ion reserve is 420 times that of lithium, the stock is abundant and the price is low, the theoretical bom cost can be reduced by 30%-40% compared with lithium battery, and the sodium battery has better safety, high and low temperature, and fast charging performance, so it has broad application space in energy storage and two-wheeler market.At present, the shortage of lithium resources limits downstream development, and the market begins to pay attention to sodium batteries with higher element abundance.

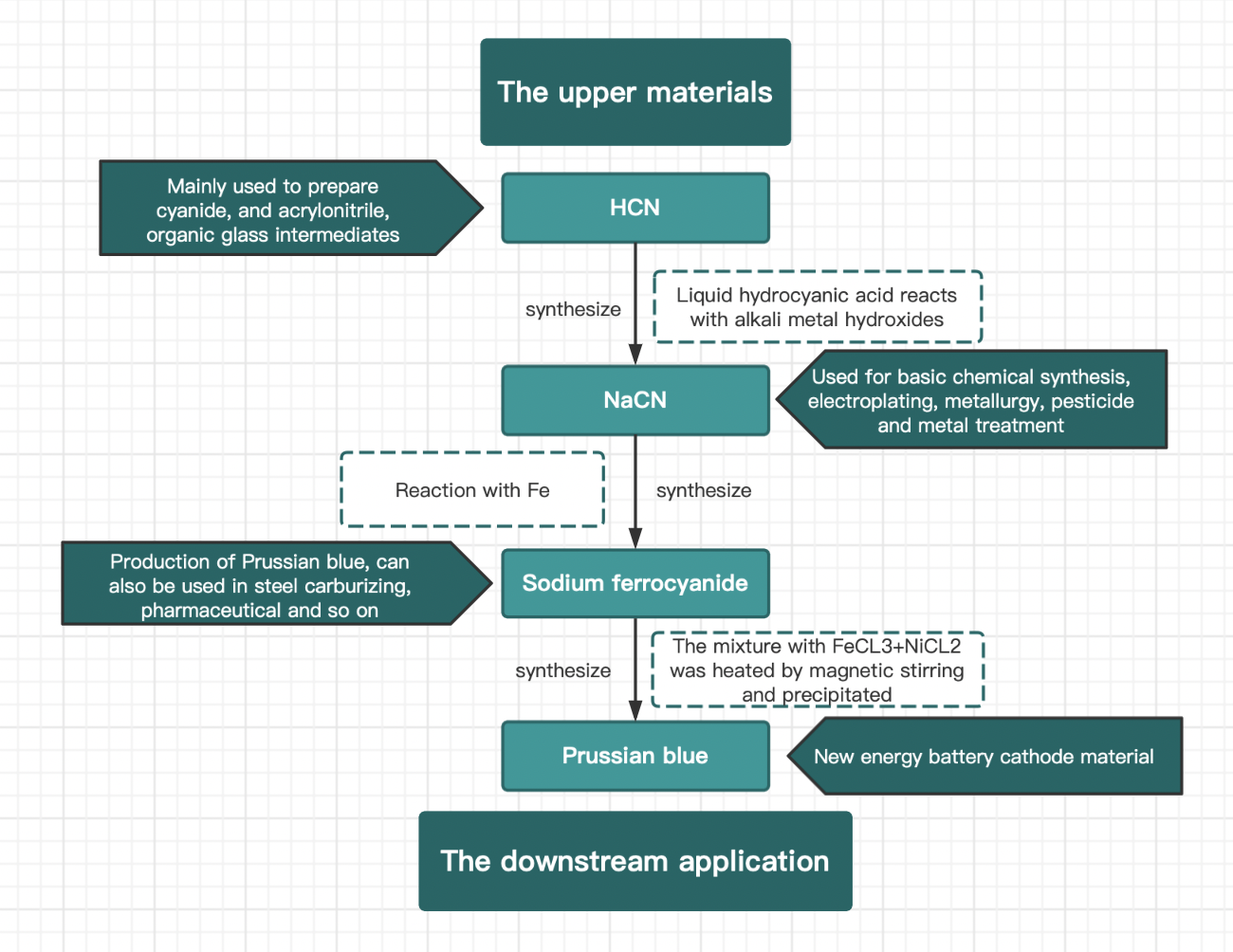

Part02 Preparation of Prussian blue cathode material

Prussian blue is a widely studied cathode material for sodium-ion batteries, which can be prepared by solution coprecipitation. The precipitant Na4Fe(CN)6 (sodium yellow blood salt) was added to the mixed solution of FeCl3 and NiCl2 at a certain concentration to generate a precipitate containing Fe and Ni cations. After filtering and washing, Prussian blue doped with Ni was finally obtained.

The precipitant Na4Fe(CN)6 (sodium yellow blood salt) used in the preparation of Prussian blue is also known as "sodium ferrocyanide". The production process principle from raw gas to Na4Fe(CN)6 is as follows:

Hydrocyanic acid synthesis reaction: CH4 + NH3 + 3/2O2 → HCN + 3H2O

Sodium cyanide synthesis reaction: HCN+NaOH→NaCN+H2O

Sodium synthesis reaction of yellow blood salt: 6NaCN + Fe+ 12H2O → Na4Fe(CN)6·10H2O + 2NaOH+ 2H2

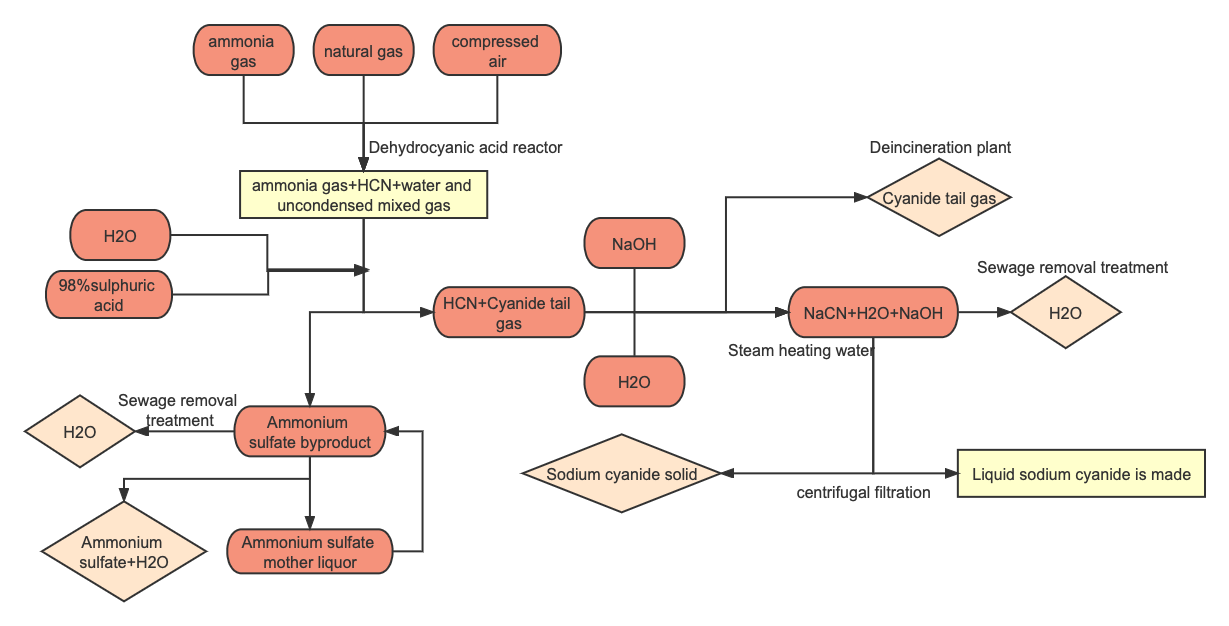

DODGEN Chemical Technology has the design experience at home and abroad in the process technology of hydrocyanic acid and its derivatives and the experience in the practice of many sets of devices in China. It has cooperated with the listed company Shandong NHU Holding group Co., Ltd. in the 100,000 tons/year liquid sodium cyanide project, and the operation has been successful, and the products have reached the world advanced level.

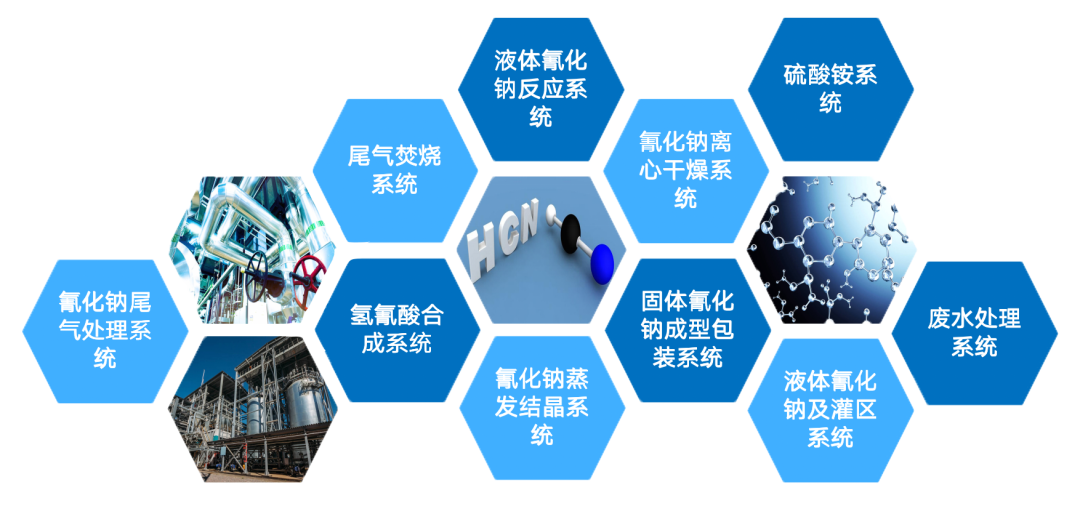

Part03 DODGEN Complete process solutions

Combined with the production needs of Shandong New NHU and its own rich engineering experience, DODGEN provides 100,000 tons/year liquid sodium cyanide production process package, complete equipment design, and by-production of ammonium sulfate and sodium sulfate. The whole process system involves more than ten units, the system is mature, reliable, high safety and full automation control.

1)Hydrocyanic acid synthesis system

The HCN synthesis system is mainly divided into two parts: HCN synthesis and HCN deamination. The deamination process adopts DODGEN's exclusive DSV absorption reactor, which has high deamination efficiency, good control level of ammonium sulfide production and continuous automatic production. At the same time, ammonium sulfide was extracted for evaporative decanting, and the decanting index and process reached the international advanced decanting process level.

2)Sodium cyanide synthesis system

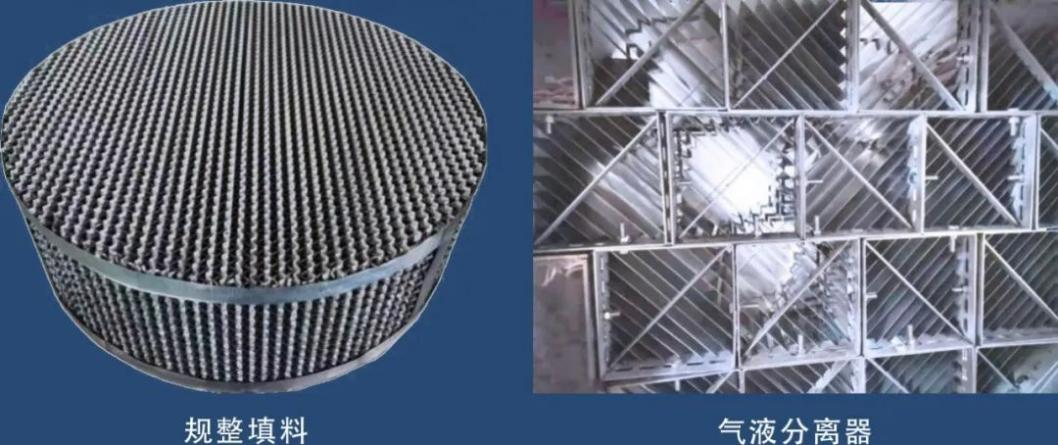

The deaminated HCN and liquid alkali are directly absorbed to synthesize liquid NaCN, and the absorption reaction is also carried out by the DODGEN DSV reactor.DSV reactor has high reaction efficiency and short residence time, which can effectively reduce the impurities of sodium carbonate produced by CO2 gas and sodium formate produced by the hydrolysis of sodium cyanide.The operation flexibility is large, the lower limit can run stably under 50% load, the side reaction produces less sodium carbonate impurities and the raw material sodium hydroxide consumption is low.In this project, the efficient gas liquid separator and structured packing provided by DODGEN play a key role in improving product purity in the NaCN unit.

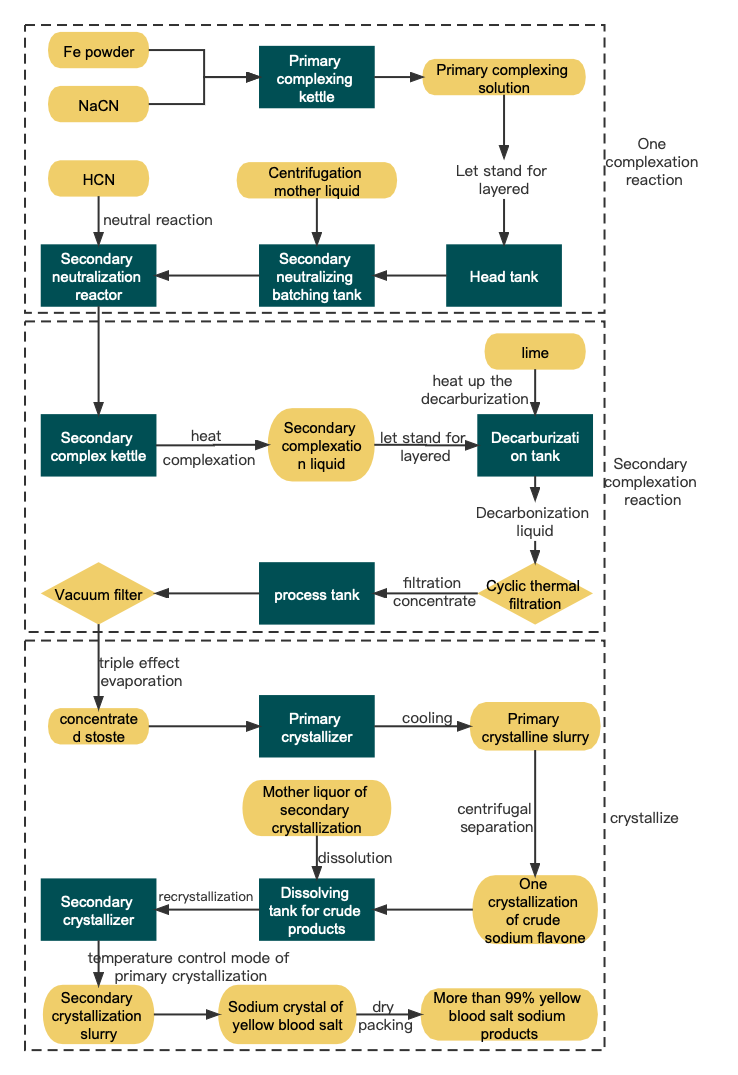

3)Sodium synthesis system of yellow blood salt

For sodium synthesis reaction process of yellow blood salt:

6NaCN + Fe+ 12H2O → Na4Fe(CN)6·10H2O + 2NaOH+ 2H2

DODGEN provides corresponding technological solutions and devices. The process flow is as follows:

With the gradual industrialization of sodium-ion batteries, nearly 30 global enterprises began to layout sodium-ion batteries, energy storage and electric vehicle applications bloom. As the key raw material of Prussian blue as the cathode material of sodium-ion batteries, the industrial layout of sodium salt is no longer far away. DODGEN deep constantly, in the field of new energy storage materials in cyanide (nitrile/Prussian blue/white) of Prussia, fluoride (LIFSI/desflurane), sulfide, polyacrylic acid/acrylonitrile, silane and other fields have a lot of reaction and separation technology, at the same time, ongoing technology iteration in response to the change of the market, meet the demand of our customers and create value.