According to a previous report by Japan's Asahi Shimbun, sources within the Japanese government revealed that the government plans to start discharging treated nuclear-contaminated water from the Fukushima nuclear power plant into the sea as early as late August.

The plan to release nuclear-contaminated water into the sea in Japan has sparked intense debates within the scientific community and among the public, with the focus on the issue of nuclear wastewater treatment. Generally, nuclear-contaminated water contains radioactive isotopes such as strontium, cesium, plutonium, uranium, and radioactive tritium. Previously, TEPCO (Tokyo Electric Power Company) removed 62 nuclides, including cesium, through cesium adsorption devices and the ALPS (Advanced Liquid Processing System) multi-nuclide adsorption system. In 2014, they added a strontium adsorption device. After the wastewater undergoes cesium and strontium removal, as well as desalination through reverse osmosis, it has three destinations: approximately 280 cubic meters of water will return to the injection tank as circulating cooling water for the reactor; the remaining water goes into the ALPS unit or the mobile strontium removal unit, and the treated effluent is finally stored in storage tanks. However, there is one isotope, tritium, that proves challenging to remove to meet standards through the ALPS system.

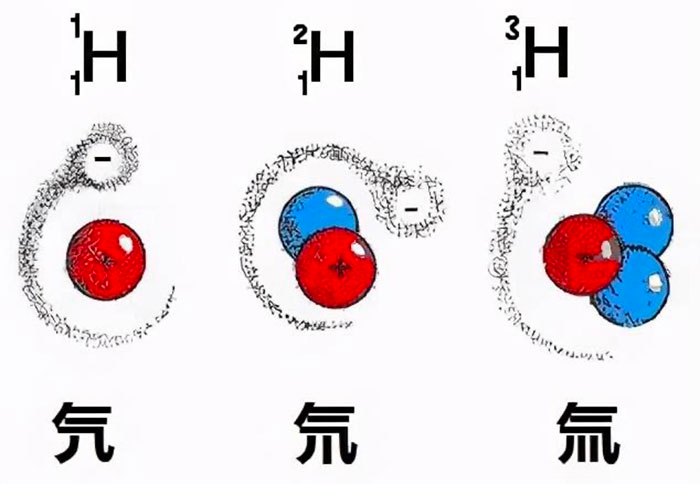

What is tritium?

Tritium is an isotope of hydrogen, and it also occurs naturally. It has a relatively low impact on the human body, but high concentrations can pose health risks. Tritiated water in conventional nuclear power plants is primarily formed due to the neutron irradiation of hydrogen isotopes in the coolant loop or the penetration of fission by-products from fuel elements into the loop.

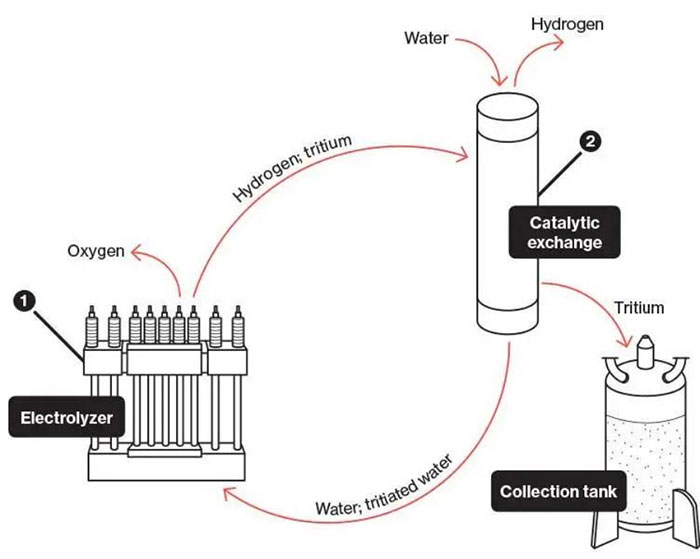

In fact, Japan has conducted extensive research and exploration efforts to address tritium. In September 2014, the Ministry of Economy, Trade and Industry of Japan selected Kurion from the United States, RosRAO (a subsidiary of the Russian state-owned atomic energy corporation Rosatom), and GE-Hitachi Nuclear Energy from Canada to undertake a tritium removal demonstration project. So, what is the highly challenging tritium removal solution like? According to information available, both Veolia (which acquired Kurion) and Rosatom employ a technology solution using the Combined Electrolysis Catalytic Exchange (CECE) process.

The Combined Electrolysis Catalytic Exchange (CECE) process, chosen by the International Thermonuclear Experimental Reactor (ITER) for tritium removal from water coolant due to its characteristics of lower operating temperature and easy process control, has also been adopted by the Tokyo Electric Power Company in Japan as a significant alternative technology for the large-scale tritium removal from nuclear wastewater following the Fukushima nuclear accident. In the CECE process, only a small fraction of the treated tritiated wastewater undergoes further processing after enrichment and concentration, while the majority is converted into gaseous hydrogen for release. The emitted hydrogen contains saturated water vapor, and tritium exists in the form of oxidized tritiated water (HTO) within the saturated water vapor, exhibiting a biological toxicity 10,000 times stronger than elemental gaseous tritium. Therefore, prior to hydrogen release, thorough treatment of water vapor is necessary, typically achieved by condensing the vapor and returning the condensed liquid to the process system.

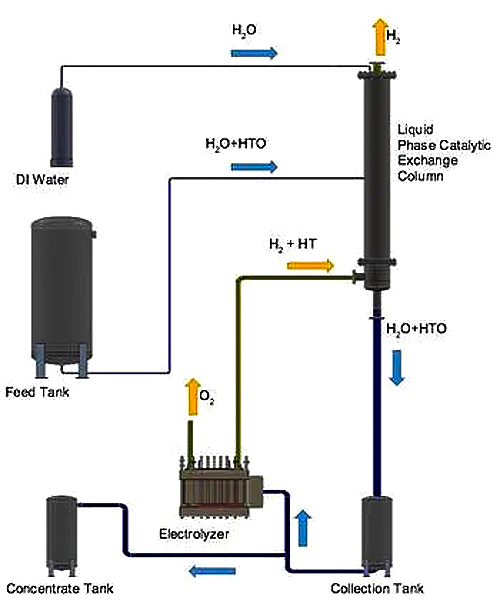

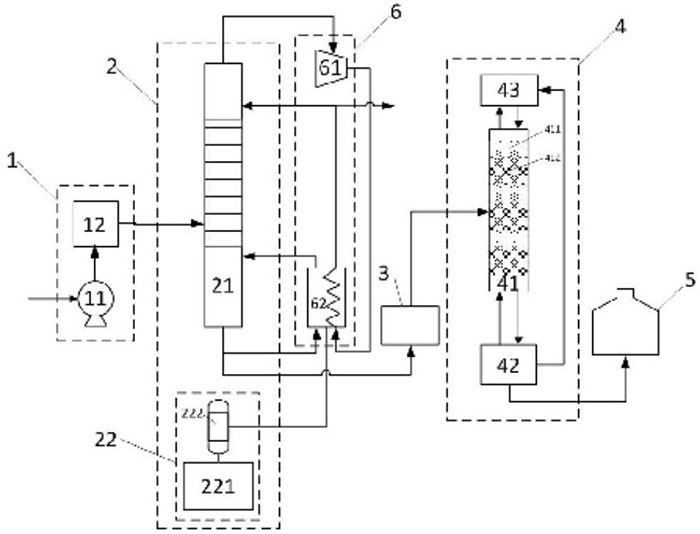

KURION's MDS tritium removal system consists of two main components: a liquid-phase catalytic exchange tower unit and an electrolysis hydrogen production unit. The liquid-phase catalytic exchange tower is filled with precious metal hydrophobic catalysts and hydrophilic packing material. The hydrogen generated in the electrolysis unit exchanges hydrogen isotopes with the downward-flowing water in the catalytic exchange tower. Tritium is enriched in the liquid-phase water and depleted in the gaseous hydrogen phase. The catalytic exchange tower is divided into two sections at the tritiated water inlet, with the upper section as the depletion stage and the lower section as the enrichment stage. Natural water flows down from the top of the depletion stage, stripping off the evolved hydrogen, and the depleted hydrogen is discharged at the top. In the enrichment stage, tritiated feedwater mixes with the water flowing down from the depletion stage, exchanging isotopes with the hydrogen. This process results in the enrichment of tritiated water at the bottom of the liquid-phase catalytic exchange tower.

While it is technically feasible to separate tritium from nuclear wastewater, the Japanese government has not practically implemented any tritium removal technology due to the underlying "cost," which is the reason for the failure to achieve industrialization. According to a report from the World Nuclear News (WNN) in November 2014, the Japanese Ministry of Economy, Trade, and Industry allocated approximately $10 million to the U.S. radioactive waste management company Kurion. The purpose was to demonstrate tritium separation technology, aiming to validate the technology and assess the establishment and operational costs for its application at the Fukushima nuclear power plant. The report noted that existing technologies for tritium separation from heavy water were considered "expensive" for handling Fukushima nuclear wastewater at that time.

In March 2015, the Los Angeles Times reported that Gaetan Bonhomme, the Chief Technology Officer of Kurion, estimated that the company's existing technology could remove tritium from 800,000 cubic meters of water within 5 to 8 years. However, the construction of the facility alone would cost $1 billion, with annual operating expenses in the millions of dollars. In April 2016, a special working group of the Japanese government concluded that the existing tritium removal technologies were not applicable to the Fukushima nuclear power plant. The report suggested that the basis for this conclusion was economic considerations rather than a lack of technological capability.

With the needs of national development and environmental protection, nuclear energy will play an increasingly important role in our country's energy sector. At the same time, it is crucial to recognize that while nuclear energy is more environmentally friendly and sustainable compared to fossil fuels, it unavoidably generates a certain amount of radioactive waste while providing vast amounts of energy. Moreover, as the scale of nuclear power expands, the generated radioactive waste will gradually increase. Due to the unique characteristics of radioactive waste, it has always been a matter of widespread concern.

Tritiated wastewater is one crucial aspect of this concern, where tritium in pressurized water reactor (PWR) nuclear power units is primarily generated through nuclear reactions. A portion is produced during the nuclear fission process, with some released when nuclear fuel elements generate and penetrate through the cladding into a loop. Another portion results from trace substances in the loop coolant, such as B, Li, and D, forming under neutron action. For a one-million-kilowatt nuclear power station, the tritium emission is approximately 70 terabecquerels per year, with tritium existing in the wastewater in the form of tritiated water (HTO). In the case of AP1000 reactor units, tritium in the loop coolant primarily enters the waste liquid treatment system (WLS) in the form of effluent from the reactor coolant system.

Tritium is radioactive and undergoes β decay, with a half-life of up to 12.43 years. Although the Chinese national standard "Basic Standards for Ionizing Radiation Protection and Radiation Source Safety" categorizes tritium as a low-toxicity radioactive nuclide, this does not imply that the hazards of tritium can be ignored. The radiotoxicity of liquid tritium (HTO/T2O) is 10,000 times higher than that of gaseous tritium (HT/T2). It can enter the body through the digestive and respiratory systems and damaged skin. Prolonged exposure or excessive accumulation in the body can lead to chronic internal radiation sickness.

Due to the absence of treatment facilities for tritiated wastewater in existing nuclear power plants, conventional methods for removing conventional radioactive nuclides, such as adsorption, filtration, evaporation, ion exchange, membrane technology, etc., are almost ineffective in separating HTO from H2O. As a result, the majority of tritium is eventually discharged into the environment. With the increasing scale of nuclear power construction, the discharge of tritiated wastewater is expected to gradually rise. This issue will become more prominent, especially with the scheduled construction of inland nuclear power plants. Due to the relatively weaker dilution capacity of inland water bodies compared to coastal nuclear power plants, the development of inland nuclear power plants must first consider the environmental impact of the substantial discharge of low-concentration tritiated wastewater or direct contamination of drinking water.

The tritiated wastewater from nuclear power plants is characterized by low concentration and a large volume for treatment. Simultaneously, there are high requirements for factors such as process simplification, safety, and cost-effectiveness. Currently, publicly available tritiated water treatment processes are mostly designed for heavy water containing tritium, often involving a dilution process that requires a significant amount of hydrogen to displace tritium from the water. The backend process of hydrogen isotope separation units involves substantial pressure and energy consumption.

In response to this situation, research institutions in China have improved the tritiated nuclear wastewater treatment process. The improvements include modifications to the feed system, water distillation unit, multi-stage system, combined electrolysis catalytic exchange unit, tritium water storage container, and heat pump energy-saving system. The two-stage processing approach involves using water distillation as the primary dilution and reduction process to achieve standard discharge dilution of high-capacity low-concentration tritiated water. The combined electrolysis catalytic exchange process serves as the secondary, highly efficient reduction process to achieve dilution and reduction treatment at different multiples of tritiated water. This method offers advantages such as a simple process, convenient equipment operation, good system stability, and high dilution and reduction factors. It effectively achieves the dilution and reduction treatment of tritiated water and holds significant engineering application value.

DODGEN has actively engaged in this field and has developed key equipment suitable for this application. For specific details, you can refer to: "Heavy Water Distillation: Selection of Wire Mesh Packing and Tower Internals."

In summary, the high cost is the primary reason why tritium removal technologies for nuclear wastewater have not been successfully industrialized. Industrialized nuclear wastewater treatment technologies must possess substantial large-scale processing capabilities to manage the vast volume of nuclear wastewater. Additionally, nuclear wastewater treatment involves high-risk radioactive substances. Any industrialized technology must ensure that it does not pose further risks to humans and the environment during the process. The safety and environmental friendliness of the chemical technology are indispensable requirements, necessitating extensive experimentation and validation.

Currently, achieving industrialization of tritium removal technologies for nuclear wastewater requires significant financial investment, making it economically unfeasible. However, it is believed that as technology continues to advance and industrialization challenges are continuously overcome, the prospect of cost reduction is on the horizon.