With the advancement of carbon neutrality, decarbonization, carbon capture, and carbon sequestration technologies continue to evolve and iterate. New processes for energy savings, decarbonization of raw materials, and various technologies such as coal-fired power plants, cement production, natural gas combined cycle power plants, integrated gasification combined cycle power plants, and carbon capture in biomass energy are continuously promoted in China. However, there is a missing piece in our technological landscape—Direct Air Capture (DAC). Direct Air Capture technology is currently the only means that can address the following three issues:

Cost-effectiveness

Scalability(Scale can be infinitely enlarged)

The ability to eliminate CO2 emissions at any given time; permanently remove CO2 from the air.

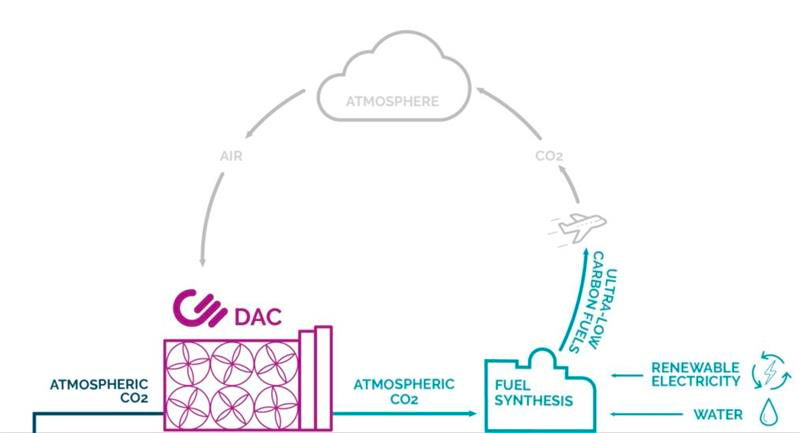

The Direct Air Capture process can be divided into three steps:

Air is drawn in through fans located inside the collector. Once drawn in, it passes through filters inside the collector, capturing carbon dioxide particles.

When the filters are fully saturated with CO2, the collector closes, and the temperature rises to around 100°C, roughly equivalent to the temperature needed to brew a cup of tea!The captured CO2, mixed with some water, is introduced underground, where it is permanently sequestered through mineralization processes.

Additionally, the captured CO2 can be converted into synthetic diesel or low-carbon fuels, used directly for power generation, or transported directly to nearby greenhouses or the beverage industry.

Direct Air Capture (DAC) Technology Classification

Based on the type of absorbent used in the Direct Air Capture (DAC) process, DAC can be classified into two categories: liquid and solid.

Liquid DAC Technology:

Alkaline Hydroxide Solution

Alkaline hydroxide solution DAC technology involves two cyclic reactions. The first reaction is the reaction between CO2 in the atmosphere and an alkaline hydroxide solution (sodium hydroxide NaOH or potassium hydroxide KOH) to produce water-soluble carbonate. The second reaction is the regeneration of the alkaline hydroxide solution through causticization, where the generated calcium carbonate (CaCO3) from the causticization reaction is heated to above 900°C to release CO2.

Amine Solution

Amine solution absorption is widely used in capturing CO2 emissions after combustion. It involves using amine solution to absorb CO2 from flue gas at ambient temperature and then regenerating the amine solution through stripping at around 120°C. Studies have found that alkyl amine has high affinity for CO2, meeting the conditions for directly capturing CO2 from the air.

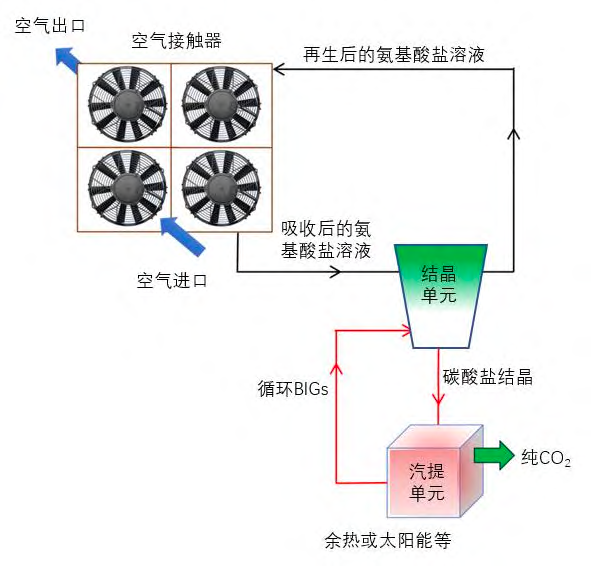

Amino Acid Salt Solution

Amino acid salt solution is used as the absorbent, converting CO2 from the atmosphere into crystalline carbonate (PyBIGH2(CO3)(H2O)4) through hydrogen bonding. The low solubility of this crystal allows for filtration and separation from the solution. The amino acid salt solution/BIGs DAC process mainly consists of three steps, as shown in Figure 2: first, CO2 in the air reacts with the amino acid salt solution to form the corresponding bicarbonate; second, the bicarbonate reacts with BIGs (Bis-iminoguanidines) to regenerate the amino acid salt and simultaneously obtain carbonate crystals; third, the carbonate crystals decompose at a lower temperature (80~120°C) to regenerate BIGs and obtain high-purity CO2.

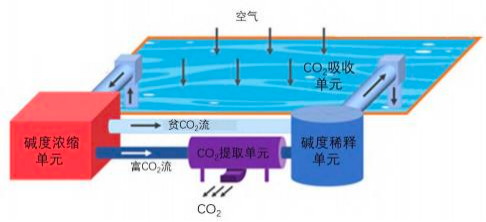

Alkalinity Concentration VariationAs shown in Figure 3, this method uses a dilute alkaline solution to absorb CO2 from the air. When the solution reaches equilibrium with the air, the alkalinity increases from the initial value to the equilibrium value. The solution is then concentrated to increase the dissolved inorganic carbon and raise the alkalinity to the maximum. As a result, the partial pressure of CO2 in the solution increases. By reducing the system pressure to below the CO2 partial pressure, the absorbed CO2 is removed and emitted. The concentrated solution is then diluted to restore the initial alkalinity, and the process repeats by continuously absorbing CO2 from the air.

Solid DAC Technology:

Solid Alkaline (Earth) Metals

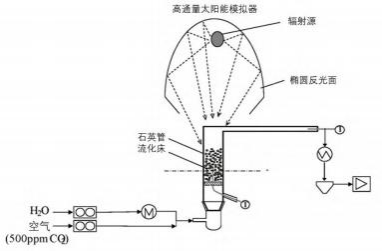

There are three types: pure alkaline (earth) metals, supported alkaline (earth) metals, and solid amine adsorbents. Taking CaO as an example:

The CO2 capture process involves two main steps: first, CaO undergoes carbonation reaction upon contact with CO2, transforming into CaCO3; second, CaCO3 is calcined to release CO2, and these two steps continue in a continuous cycle. The oxides or hydroxides of alkaline (earth) metals can also be applied to capture CO2 from the air. However, due to the much lower concentration of CO2 in the air compared to flue gas, the energy required for direct air capture of CO2 from the air is significantly higher.

MOFs Materials

In recent years, MOFs have become a research hotspot in the DAC field. Strong CO2 adsorption capacity can be achieved by loading amine groups on MOFs (Section 3.2) or adjusting pore size and distribution of active sites. Shekhah et al. studied the performance of SIFSIX-3-Cu/Ni/Zn in direct air capture of CO2. By adjusting the metal type to change the unit cell and pore distribution, they found that the pore size is the largest when the central particle is zinc (Zn), corresponding to a CO2 adsorption capacity of 0.13 mmol/g. When the central particle is copper (Cu), the pore size is the smallest, allowing adsorption of 1.24 mmol/g of CO2.

Humidity-Responsive Adsorption

Humidity-responsive adsorption DAC mainly involves three steps: first, in a dry environment, alkaline groups (OH- or CO32-) on the adsorbent surface adsorb CO2 from the air; second, under conditions of higher humidity or higher hydration, the adsorbed CO2 gradually desorbs; third, the desorbed CO2 is compressed and stored or utilized.

Companies Achieving DAC Industrialization

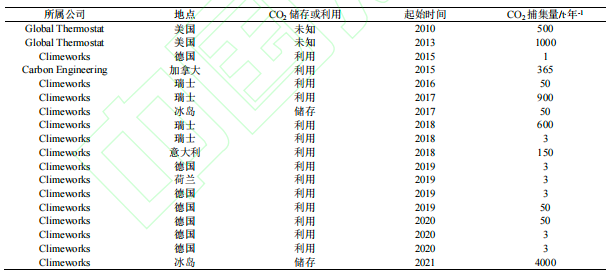

Currently, several companies, including Climeworks in Switzerland, Carbon Engineering in Canada, and Global Thermostat in the United States, have been dedicated to DAC technology research for many years and have successfully operated multiple DAC projects.

Climeworks Overview: Founded in Switzerland in 2009, Climeworks started as a branch of the Swiss Federal Institute of Technology in Zurich. In 2014, Climeworks collaborated with Sunfire and Audi to launch the first pilot plant, capable of capturing and converting 80% of CO2 from the environment into synthetic diesel. In 2017, Climeworks AG successfully operated the world's first industrial-scale direct air capture (DAC) plant, capturing 900t CO2 annually, with the captured CO2 directly delivered to nearby greenhouses or the beverage industry. Climeworks' DAC project named Orca in Iceland was the world's first operational DAC project, starting construction in August 2020 and officially operating in September 2021, capturing 4000t CO2 annually. In June 2022, Climeworks announced the initiation of the second DAC project named Mammoth, capturing 36,000t CO2 annually, expected to start operations in 2024.

Carbon Engineering (CE) Overview: CE was founded in Canada in 2009 by Professor David Keith from Harvard University. In 2017, CE collaborated with researchers from Harvard University to develop an industrial production method for directly capturing CO2 from the air and using it for liquid fuel production. In 2021, CE established the Carbon Engineering Research Center and created the world's largest DAC research equipment. Subsequently, CE, in partnership with Oxy Low Carbon Ventures, initiated a 1 million-ton air carbon capture and storage project near the OXY oilfield. CE also collaborated with Pale Blue Dot Energy to deploy a commercial DAC project in the UK. In 2022, CE partnered with 1PointFive to complete the process design of the world's first million-ton large-scale commercial DAC project. After the project becomes operational, it is expected to capture 500,000t CO2 annually, with the capacity to expand to 1 million tons per year. 1PointFive and CE announced plans to complete 70 such large-scale DAC facilities by 2035.

Global Thermostat Overview: Established in the United States in 2010, Global Thermostat was founded by authors of the Kyoto Protocol and researchers from Princeton, Harvard, Columbia, and Stanford Universities. The company built its first pilot demonstration plant in the same year and the first commercial demonstration plant in 2013. Currently, Global Thermostat is collaborating with ExxonMobil to advance its carbon capture technology and scale it up. In April 2021, Global Thermostat signed an agreement with HIF to supply DAC equipment to the pilot plant in Chile, Haru Onie Fuels, and use captured CO2 mixed with electrolytic hydrogen to produce synthetic gasoline. The DAC plant's design goal is 2000t CO2/year.

Currently, there are nearly a hundred planned and operational carbon capture, utilization, and storage (CCUS) demonstration projects in various industries such as power, oil and gas, chemicals, cement, and steel in China. Over half of these projects have been completed and put into operation, with a total carbon capture capacity exceeding 4 million tons per year. The development of direct air capture (DAC) technology in China started relatively late, and there is currently no operational DAC industrial demonstration facility. State Power Investment Corporation (SPIC) has proposed to complete the construction of China's first DAC industrial demonstration facility by 2024, aiming to address the gap in the DAC engineering demonstration field in the country. Zhejiang University has developed a small-scale DAC prototype with a capacity of 30kg/day using the wetting regeneration process, and the captured CO2 can be utilized to supply agricultural greenhouses.

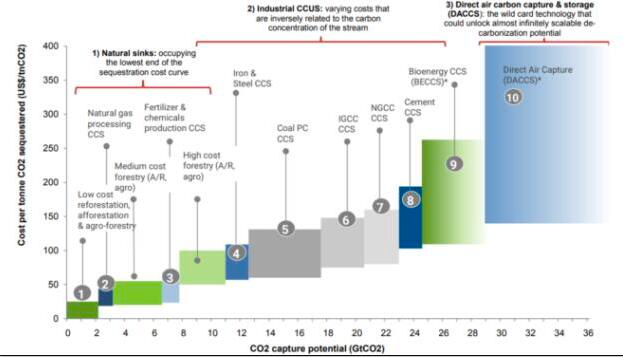

What is the development potential of DAC technology? The chart below depicts the marginal cost curves for different carbon capture routes:

Data source: Goldman Sachs Global Investment Research

It can be seen that DAC technology has unlimited potential for capacity increment. When reaching 29Gt CO2, marginal costs decrease, highlighting the commercial potential.

International Efforts in Developing Direct Air Capture (DAC) Technology

In response to global warming, the U.S. Department of Energy announced a $1.2 billion subsidy for two Direct Air Capture (DAC) projects on August 11. These projects are located in Texas and Louisiana, respectively. The Department of Energy estimates that once completed, these projects will remove over 2 million tons of carbon dioxide from the atmosphere annually, equivalent to reducing the yearly emissions of approximately 445,000 fuel-efficient cars, while also creating 4,800 jobs in the two regions.

According to the Bipartisan Infrastructure Law, the United States plans to establish four DAC centers over the next decade, with the federal government providing $3.5 billion in subsidy support, of which the mentioned $1.2 billion is part. The Department of Energy states that, with widespread deployment, DAC can help the United States achieve its goal of greenhouse gas neutrality by 2050.

China's Fourth National Climate Change Assessment Report, released in 2022, explicitly mentions Carbon Capture, Utilization, and Storage (CCUS) technologies, including Bioenergy with Carbon Capture and Storage (BECCS) and Direct Air Capture (DAC), as negative emission technologies. In the same year, the National Development and Reform Commission and the National Energy Administration, in their "Opinions on Improving the System Mechanism and Policy Measures for Energy Green and Low-Carbon Transformation," clearly expressed China's encouragement of the development of low-carbon technologies. Carbon capture is considered a crucial pillar for China to achieve its climate goals. It can be said that DAC technology holds significant strategic importance for China in realizing its carbon neutrality objectives.

Furthermore, major industry players are increasingly investing in DAC. Companies such as Alphabet, Shopify, Meta, Stripe, Microsoft, and H&M Group have committed to jointly purchase nearly $1 billion in "permanent carbon removal" technologies from 2022 to 2030. In May of this year, JPMorgan Chase reached a $20 million, nine-year carbon removal agreement with Climeworks, a DAC pioneer based in Switzerland.

DAC technology is an indispensable component of carbon neutrality strategies, but its cost remains a challenge for commercial viability. DAC's potential applications in the petroleum industry, manufacturing synthetic fuels, plastics, methanol, concrete, and various other products provide room for imagination. DAC is in its early stages in China, and DODGEN is actively involved in technological research and development. We welcome more partners to join us in promoting the rapid development of this field.